How COREbeat Helped Tharsis Mining Prevent a Critical Fault

Eleni Natsi & Alexandros Patrikios | October 10th 2025

How COREbeat Helped Tharsis Mining Prevent a Critical Fault

Early warnings averted a costly lab shutdown

In mining, even the smallest anomaly can set off a chain reaction of costly disruption. For Tharsis Mining in Andalusia, Spain, a loose hook on a ventilation fan could have threatened the clean air supply, stressed key components, and eventually forced a shutdown.

Instead, thanks to COREbeat - the predictive maintenance platform developed by CORE Innovation Group - the fault was detected early, addressed quickly, and permanently resolved before it could spiral out of control.

A Critical Alert at Tharsis Mining

In June 2025, COREbeat flagged unusual readings from the LQ50 fan in Tharsis Mining’s analytical, metallurgical, and R&D laboratory. The fan plays a crucial role: supplying clean air to analysis and office rooms while extracting contaminated air.

A site inspection revealed a displaced filter caused by a loose mechanical hook. The team adjusted it, and the alert cleared. But within 24 hours, COREbeat raised the same alarm again. On closer inspection, engineers discovered the root cause: the hook itself was faulty and unable to hold the filter securely.

By replacing the component, Tharsis ensured the ventilation system returned to full reliability - and avoided a costly failure that could have reduced airflow, overworked the motor, increased vibration, and prematurely worn-down bearings and couplings.

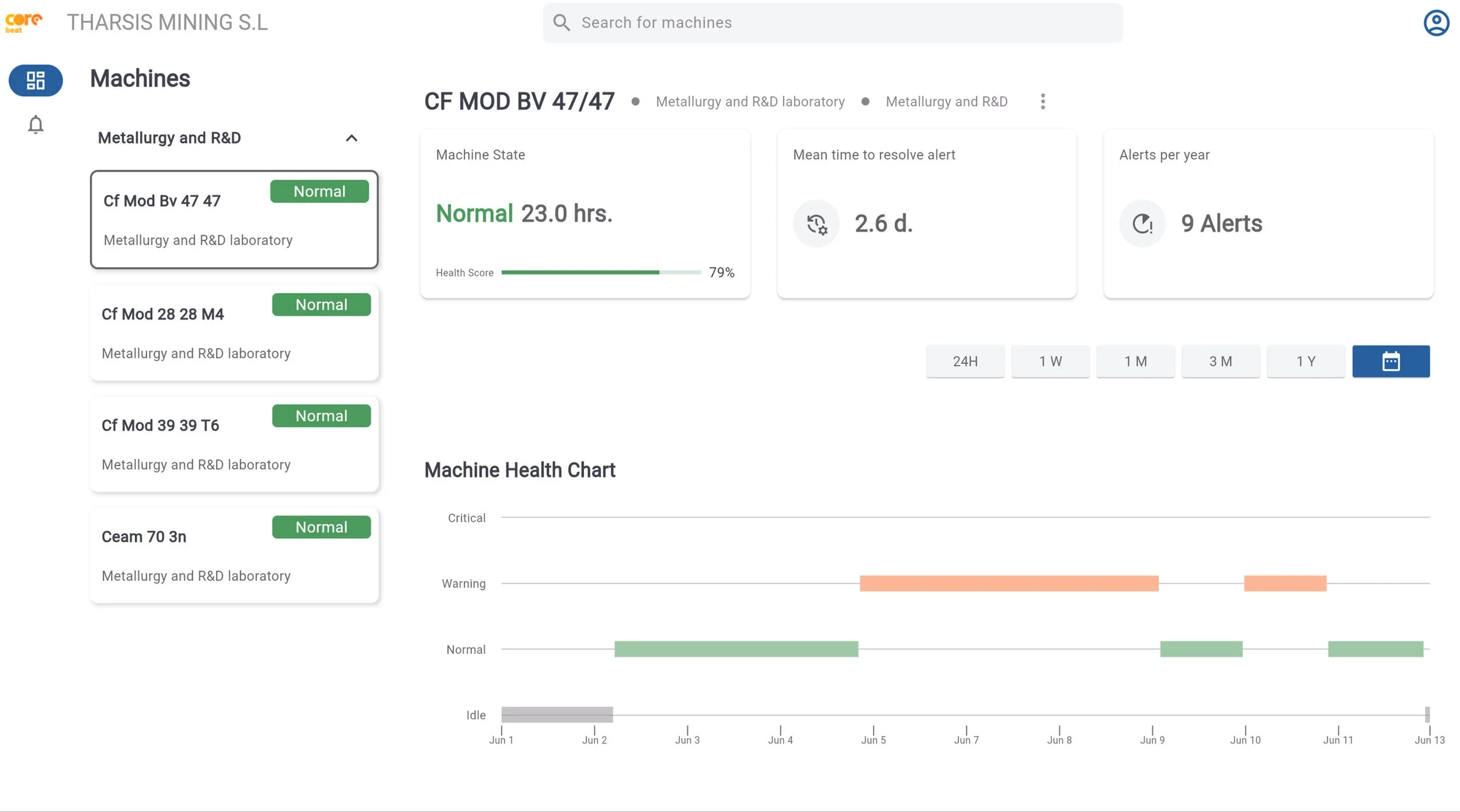

The alert received by maintenance staff, as shown in the COREbeat UI

“A Partner in Predictive Maintenance”

As Tamara Martínez-Santos Manjavacas, R&D Engineer at Tharsis Mining, explains:

“Our laboratory ventilation system is equipped with vibration and temperature sensors on the motors, all monitored through the COREbeat platform. When the system alerted us to an anomaly, our team investigated, identified the faulty hook, and acted immediately. Thanks to COREbeat’s early warning, we avoided a major shutdown and additional costs. This case demonstrates the value of continuous monitoring, advanced analytics, and teamwork in extending equipment life and safeguarding operations.”

COREbeat’s dashboard in action - from the first alert to the final resolution

Why It Matters

At first glance, a faulty hook may sound insignificant. But for a facility that handles metallurgical testing and pilot-scale experiments, reliability is everything. Any disruption in airflow could compromise the safety of the workspace, the accuracy of results, and the efficiency of ongoing tests.

The Tharsis Mining case underscores a broader truth: predictive maintenance isn’t about fixing machines after they break - it’s about preventing issues before they can affect people, processes, or performance.

This success is part of the MASTERMINE project, an EU-funded initiative driving innovation in smart, autonomous, and sustainable mining. Within the project, the CORE Innovation Centre (CORE IC) has been refining and validating COREbeat across mines in Greece, Spain, Finland, and South Africa - enhancing its edge analytics and demonstrating its scalability in real-world conditions.

Through their collaboration in MASTERMINE, Tharsis Mining and CORE IC are proving how innovation rooted in real operational challenges can reshape the mining sector - making operations not only more efficient but also safer and more sustainable.

The COREbeat Advantage

Developed by CORE Innovation Group, COREbeat brings together hardware, AI, and user-friendly interfaces in a single platform:

beatBox edge-compute devices, COREbeat’s hardware component, connect to critical points of the machine to gather real-time vibration, temperature, and operational data - analysing them on the edge and running inference in real time. Custom AI algorithms learn the “beat” of each machine, identifying subtle shifts in behavior that indicate future faults.

Web and mobile apps provide plant operators with accessible, intuitive monitoring and alerts.

COREbeat installation on the LQ50 fan