Optimise your business.

Today.

An end-to-end predictive maintenance platform powered by IoT, Edge Computing, and AI.

Downtime doesn’t just stop machines, it stops progress.

When a critical asset fails, production halts, costs rise, and efficiency drops. Most maintenance remains reactive, leaving operators blind to what’s coming next.

COREbeat changes that, transforming maintenance from an afterthought into a strategic advantage.

Plan your maintenance and lower your operational costs by at least 30%.

15–25%

reduction in failures

10–15%

lower maintenance costs

5–10%

improvement in reliability

10–20%

increase in uptime

Turning Machine Data into action.

From the shop floor to the cloud, COREbeat turns real-time data into predictive insights, identifying early signs of equipment failure before they impact operations.

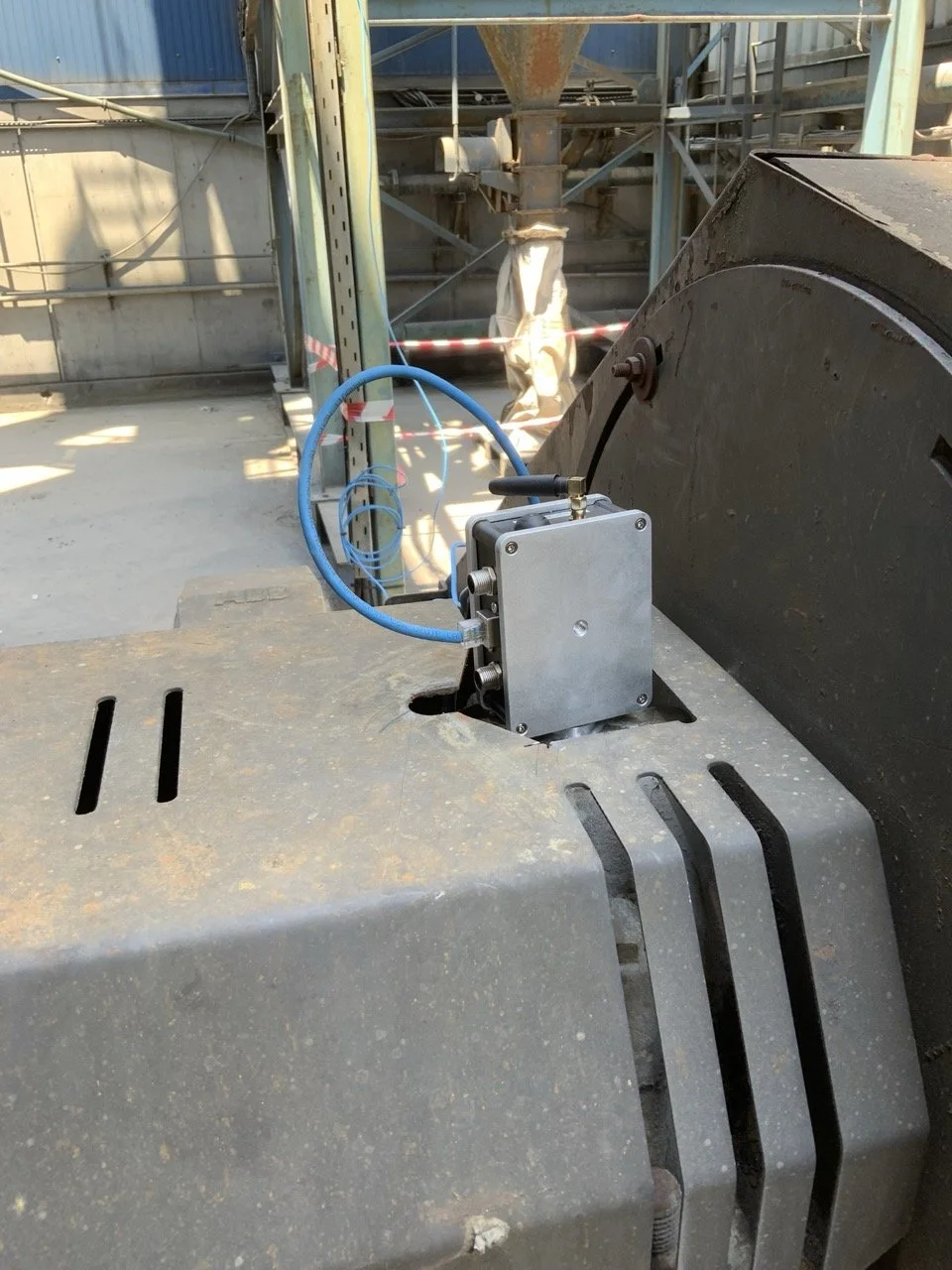

beatBox Edge

Devices

Installed at critical machine points, the IP68-rated beatBox measures vibration, temperature, and operational data from surrounding equipment.

With built-in edge computing, it performs real-time analysis directly on site, ensuring instant and reliable responses.

AI & Cloud

Intelligence

Our custom AI algorithms continuously learn the “beat” of each machine, detecting subtle behavioral shifts that signal potential faults.

Data is securely stored and processed in the cloud, turning multiple complex signals into reliable predictions.

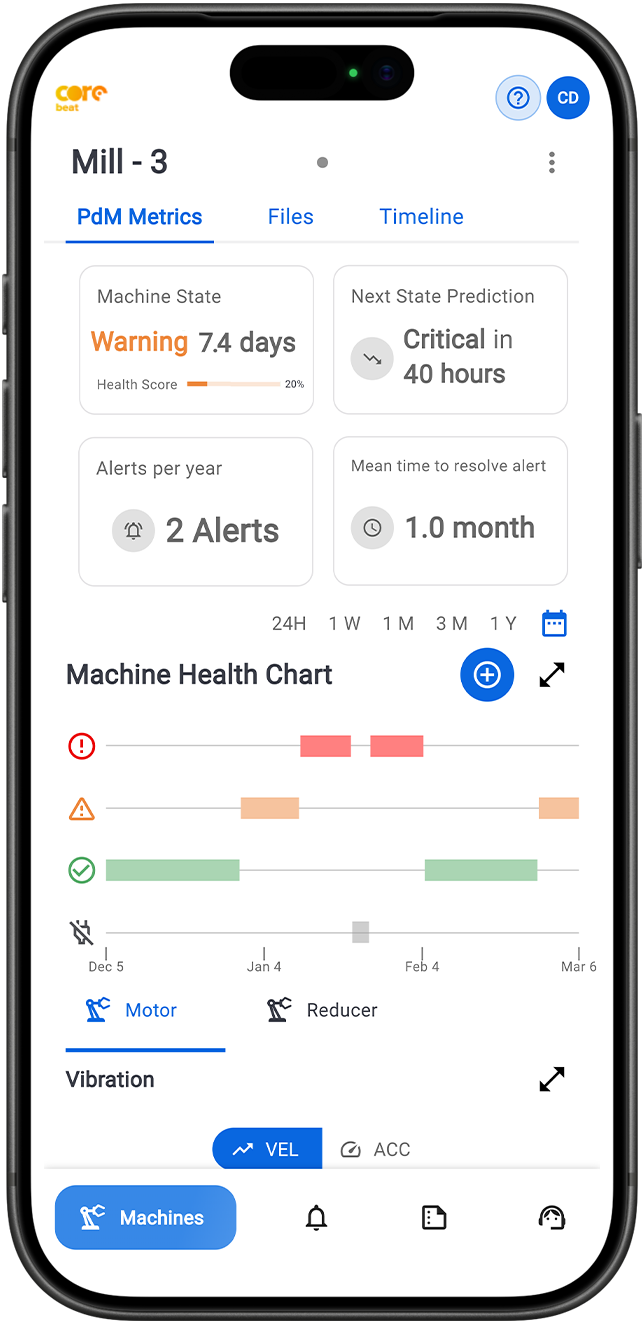

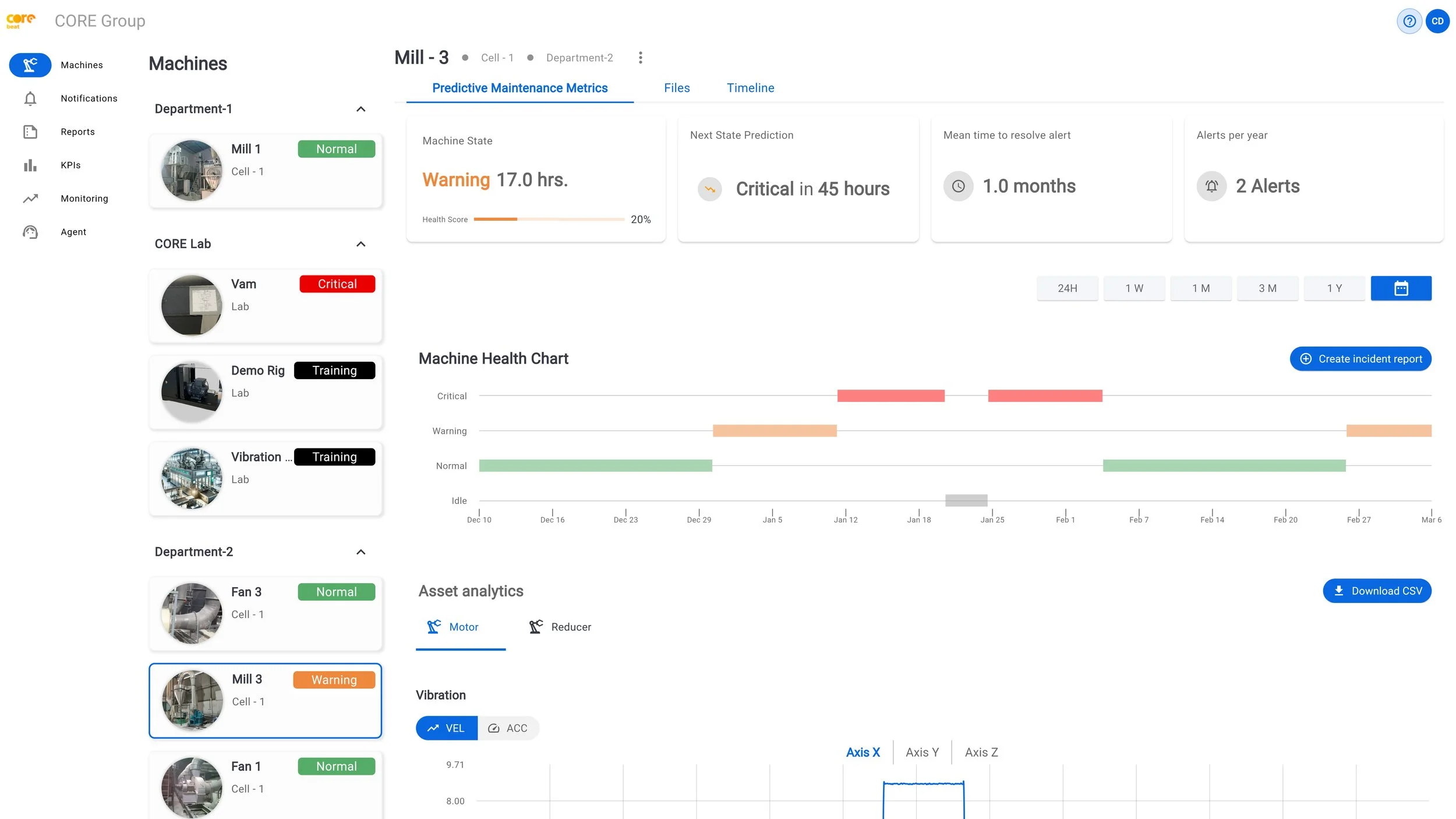

Web & Mobile

Dashboards

Intuitive monitoring software gives operators a clear, actionable overview of equipment status.

Through interactive dashboards on web and mobile, users can visualise results, receive alerts, produce reports, and monitor the timeline of each machine, acting before a failure occurs.

Get started in only 2 hours

Powered by CORE AI

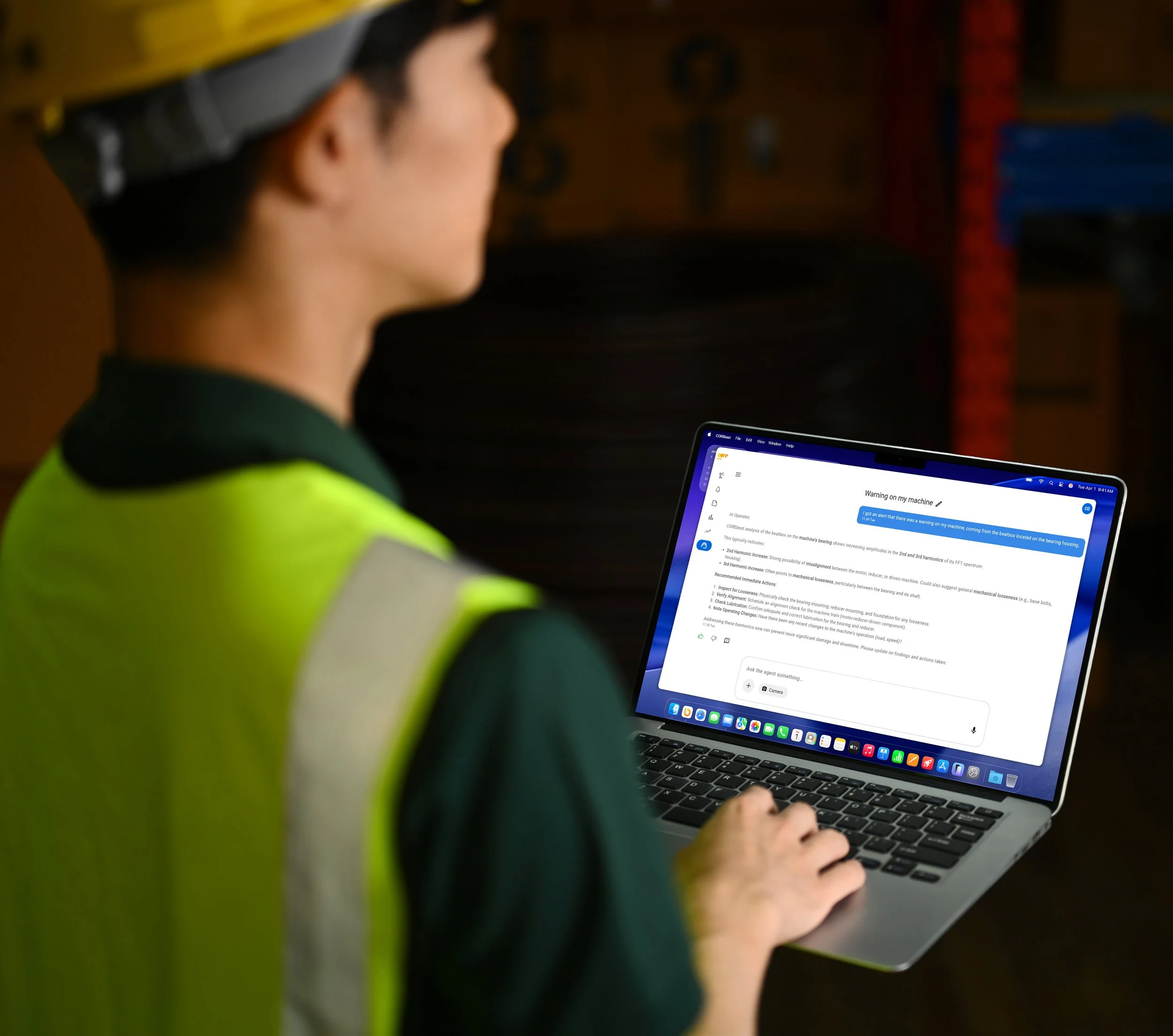

Talk to your machine

Ask the AI Agent for maintenance suggestions, performance insights, or scheduling advice directly through an interactive assistant.

Your Partner for Operational Excellence

More than maintenance, operational intelligence in motion. COREbeat empowers industries to see, understand, and act faster.

Powered by CORE AI

PLC Integration

Connect seamlessly with your existing control systems.

Production Monitoring

Track OEE, energy use, and performance in real time.

Predictive Maintenance

Monitor machine health and predict the next state with real-time health scores and alarms.

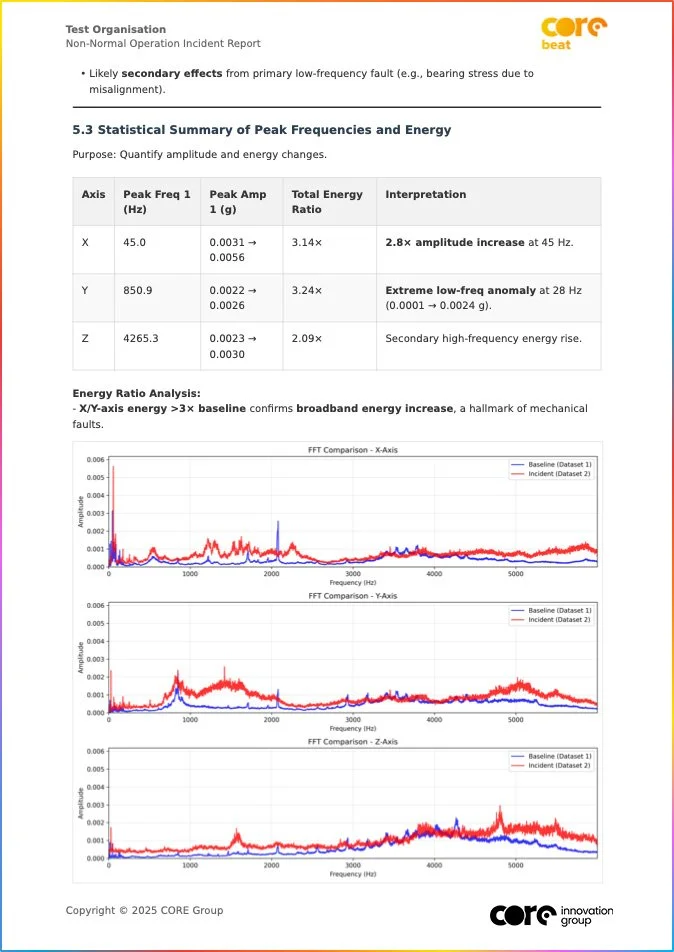

Incident Reports

AI-generated summaries explain root causes and trends.

Real Stories,

Real Impact.

Trusted by organisations that can't afford failure.

“Thanks to COREbeat’s early warning, we avoided a major shutdown and additional costs. It’s a true example of how data and collaboration extend equipment life and safeguard operations.”

Tamara Martínez-Santos Manjavacas

R&D Engineer

Tharsis Mining

“COREbeat detected a blower anomaly that could have caused serious disruption to our wastewater treatment process. Early detection prevented downtime and protected critical infrastructure.”

Nikolaos Tsalas

Research Associate

EYDAP

“COREbeat’s predictive alerts helped us prevent unexpected downtime and production losses.It detected a hidden motor belt issue that standard maintenance had missed.”

Antonios Souvatzis

Maintenance Manager

EP.AL.ME. (Metlen Group)

“COREbeat allowed us to act before a major breakdown occurred. Early warnings on our gangsaws helped us plan maintenance in time and avoid costly interruptions.”

Matteo Moioli

Operations Manager

Marini Marmi