Optimise your business.

Today.

An end-to-end predictive maintenance platform powered by IoT, Edge Computing, and AI.

Downtime doesn’t just stop machines,

it stops progress.

Planned vs unplanned maintenance can lower hourly costs by up to 35% — COREbeat makes that possible.

Across industries, COREbeat helps operators take control of their equipment before downtime strikes. From wastewater treatment to mining, COREbeat delivers measurable performance gains where it matters most.

15–25%

reduction in failures

10–15%

lower maintenance costs

5–10%

improvement in reliability

10–20%

increase in uptime

When a critical asset fails, production halts, costs rise, and efficiency drops. Most maintenance remains reactive, leaving operators blind to what’s coming next.

COREbeat changes that — transforming maintenance from an afterthought into a strategic advantage.

Anticipate

failures.

Optimize

performance.

Extend

asset life.

Turning Machine Data

into action.

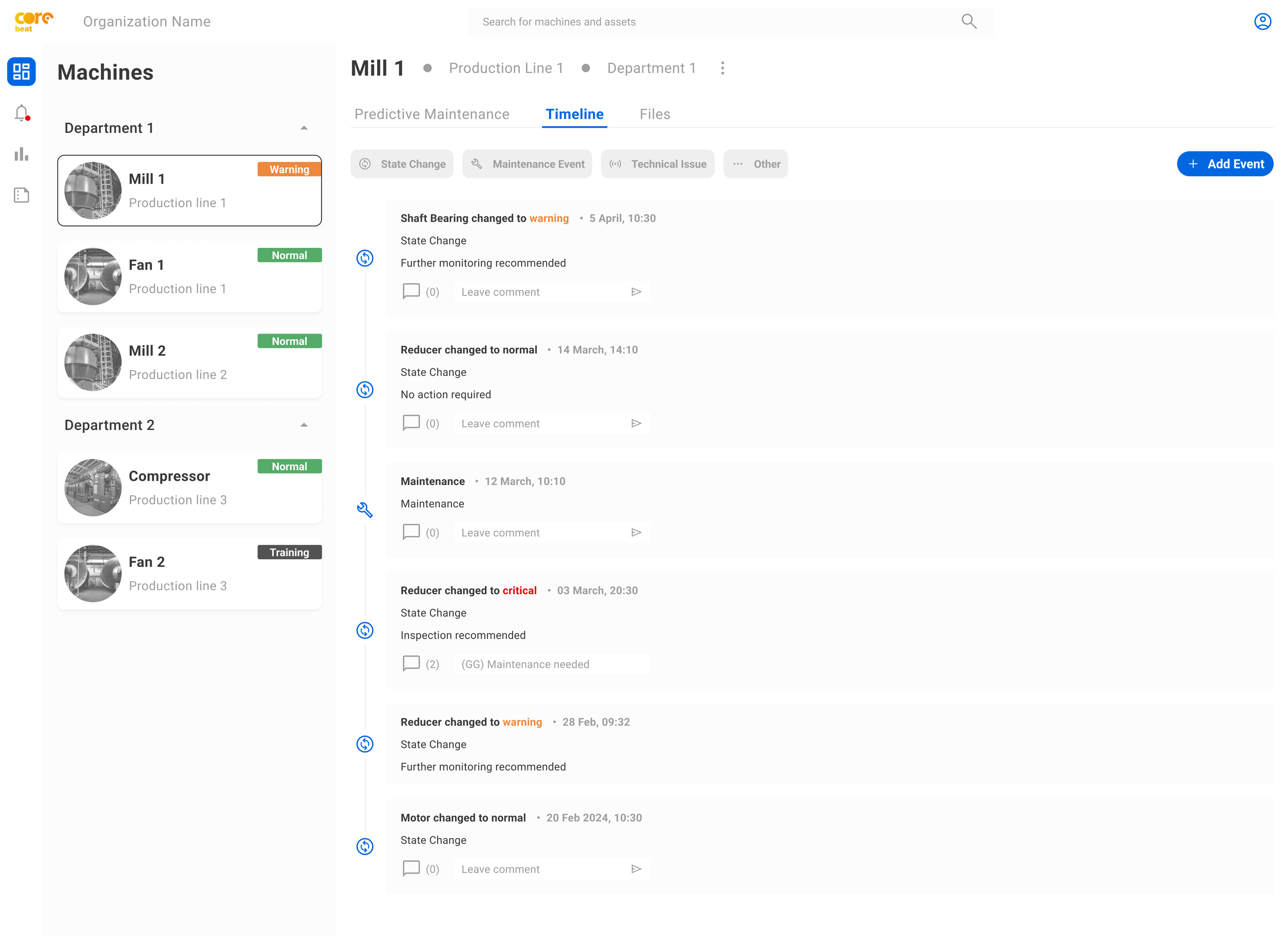

From the factory floor to the cloud, COREbeat transforms real-time data into predictive insight — learning each machine’s unique rhythm to detect what others miss.

Enable advance warning of downtime risks

Get early warnings for maintenance suggestions transforming maintenance from an afterthought into a strategic advantage.

Talk to your machine

Ask the AI Agent for maintenance suggestions, performance insights, or scheduling advice directly through an interactive assistant.

Your Partner for Operational Excellence

COREbeat interconnects all aspects of industrial operations

Sensor Data

beatBox edge device for real-time monitoring

PLC Integration

Works with existing control systems

Production Monitoring

Track OEE, energy & performance KPIs

Predictive Maintenance

AI-powered failure prediction

Powered by Ai

AI Agent

Talk to your machine

Incident Reports

Automated AI-generated insights