News

The CORE news hub

Nurturing leadership and soft skills at CORE Group

Author: Antigoni Nikolaidi

June 7th 2024

At CORE Group, our mission is to empower people, industries, and organizations to reach their full potential. We believe that continuous self-development and the enhancement of soft skills are crucial to this journey.

Recently, our management team had the opportunity to immerse themselves in a transformative 3-day leadership workshop held at our offices.

Our CORE goal

This workshop, facilitated by the experts at Game Tree, was meticulously designed to align with our CORE company values. At CORE Group, we are committed to a simple yet profound goal: to be better in six months than we are today. This commitment to growth drives us to continually seek new skills and identify areas for improvement.

The workshop

Game Tree, renowned for their expertise in HR training and development, guided our team through an engaging and interactive series of training sessions. These sessions focused on enhancing leadership skills, fostering better communication within teams, and exploring innovative management approaches. Through dynamic games and activities, our managers learned new strategies for effective collaboration and team communication.

The workshop was more than just a training session. We place immense value on our people, and it is vital for us to work cohesively as a team in our day-to-day operations while also striving to achieve our long-term objectives. The right training, coupled with essential soft skills and practical tools, helps us cultivate an interactive and inclusive workspace.

We extend our heartfelt thanks to Game Tree for their exceptional facilitation of the workshop. Their expertise and innovative approach provided our team with a highly informative and enjoyable experience.

At CORE Group, we are dedicated to fostering an environment where continuous improvement and personal development are not just encouraged but celebrated. This workshop is a testament to our commitment to building a brighter, more collaborative future for our team and the industries we serve.

Our CORE team at Beyond Expo

Author: Alexandros Patrikios

April 29th 2024

Beyond Expo took place this past week, and our team couldn’t miss out.

It’s our second time participating at the event, and we were very excited to meet all our industry friends and participate in some very insightful discussions.

Preparing for the event

Before leaving for the event, we were invited by Naftemporiki TV to talk abour CORE Group, our participation in Beyond Expo, and the AI in manufacturing landscape in Greece and beyond. We were very happy for the last minute call, and for getting the chance to reach a wider audience for CORE Group and its partners.

You can watch the brief interview by Dr Nikos Kyriakoulis, Co-Founder and Managing Partner of CORE Group, in the link below.

Engaging with the community

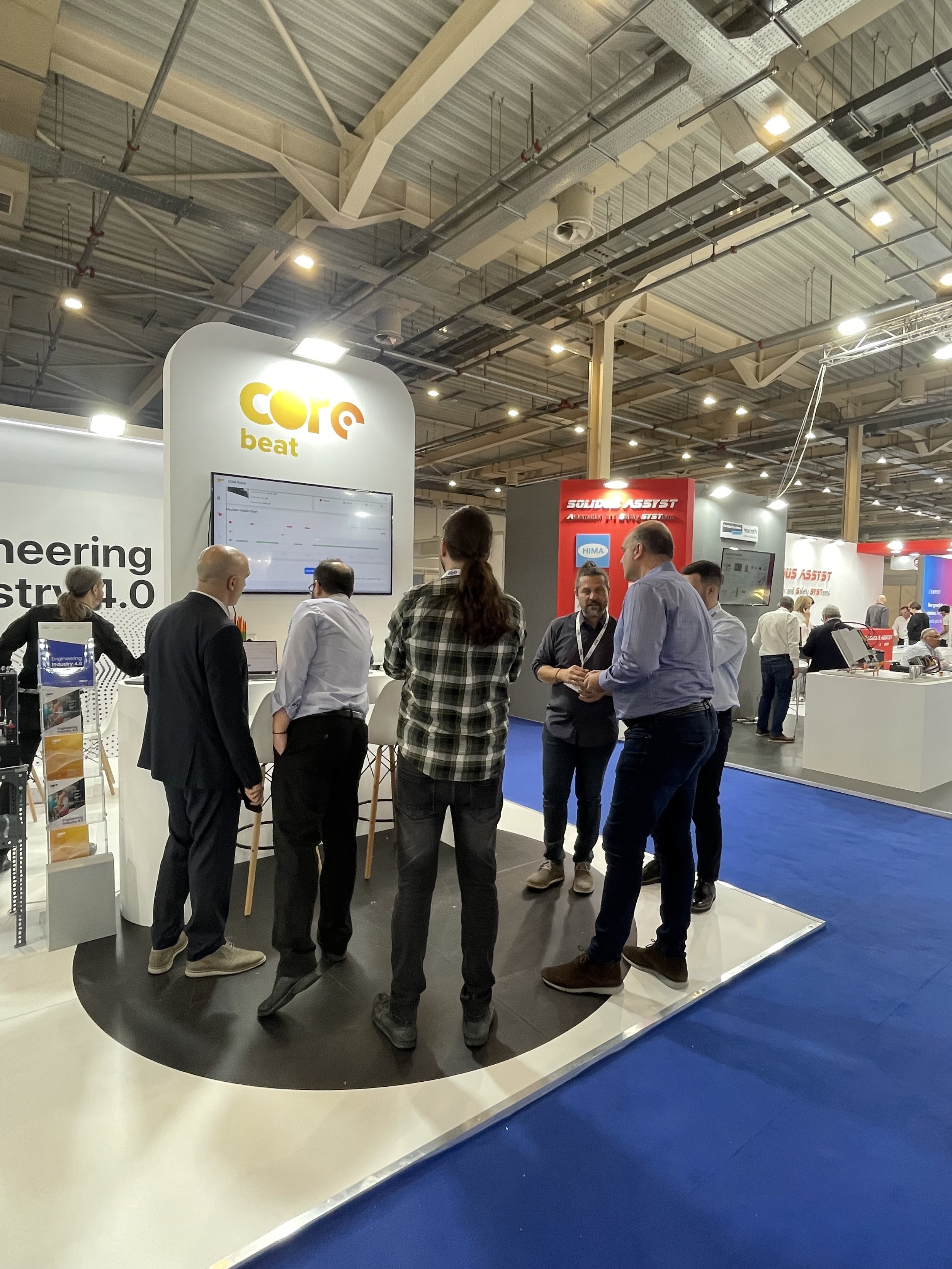

Throughout the three-day event, we had the pleasure of engaging with many attendees stopping by our booth.

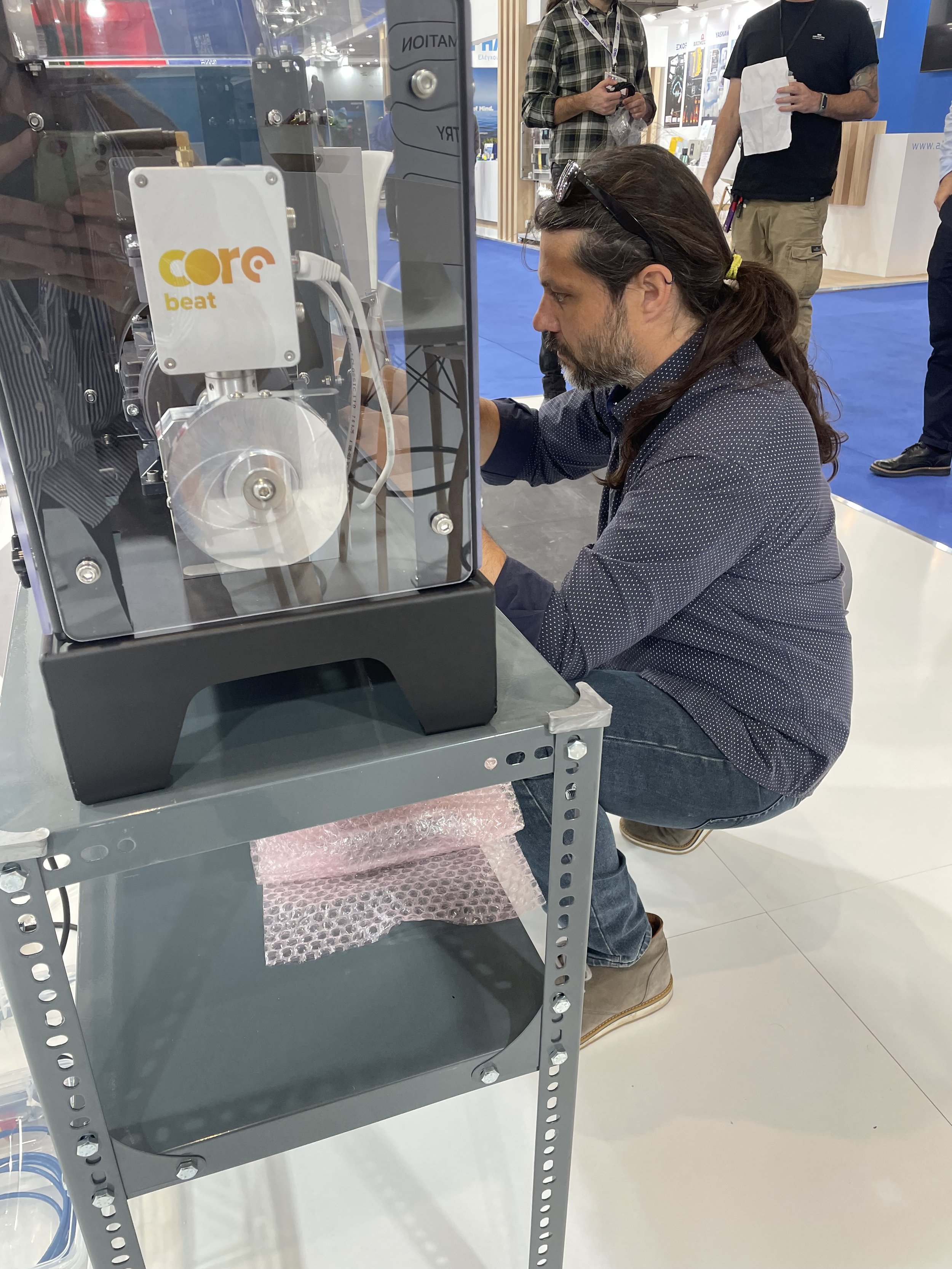

The expo was an interesting mix of industry veterans and AI enthusiasts, all of whom were very excited to see our Predictive Maintenance platform, COREbeat, in action. Our showcase included a motor connected to a beatBox, COREbeat’s hardware component, and visitors were allowed to push a nail in the machine and watch COREbeat’s UI platform spot the malfunction in near-real time. COREbeat already counts many pilots, with the ELEXIA project pilot also shown at the event.

Visitors also got to learn more about our Research & Innovation initiatives through the CORE Innovation Centre, with a focus on the pioneering Greek Smart Factory concept of our Twin4Twin project.

Industry Panel Discussions

Our managing partners, Nikos Kyriakoulis and Stefanos Kokkorikos, were invited to participate in two separate panel discussions, discussing the latest developments in machine learning and AI.

Nikos Kyriakoulis took part in a panel discussion hosted by HETiA and SEKEE, talking about innovation in the industry and opportunities specifically for SMEs.

Stefanos Kokkorikos participated in the main conference of the event, introducing CORE Group and talking about the next best in AI. You can watch the discussion here.

As part of our participation in the expo, Stefanos Kokkorikos was also invited to introduce CORE Group to the conference audience through a brief interview. You can watch the video below.

Stay in touch

A big big thank you to everyone who took the time to stop by our booth and say hi!

We look forward to staying in touch, collaborating, and all the exciting things we can achieve, together.

See you all soon!

CORE Group at the 1st Automation & Robotics Expo

Author: Alexandros Patrikios

April 23rd 2024

The 1st Automation & Robotics Expo was held from April 12 to April 14 in Athens, Greece, and the CORE Group team had to be there.

It was an exciting event full of the latest industry innovations in automation, inspiring insights, and some very meaningful connections.

The CORE Group showcase

Visitors stopping by our booth got an exciting first look at COREbeat, our all-in-one Predictive Maintenance solution, through a live demo rig. Our showcase included a motor connected to a beatBox, COREbeat’s hardware component, and visitors were allowed to push a nail in the machine and watch COREbeat’s UI platform spot the malfunction in near-real time. You can find out more information about COREbeat here.

We also got to offer some insights into our ground-breaking research and innovation initiatives, spearheaded by CORE Innovation Centre, with an exclusive first look at the Greek Smart Factory concept which we are working on, alongside our Twin4Twin project consortium. We also got to showcase the great work our Teaming.AI consortium is doing, helping Industry overcome its lack of flexibility, through the development of human-AI collaboration platform.

Engaging with the community

Throughout the expo weekend, our team had the pleasure of engaging with numerous attendees, from industry veterans to eager-eyed newcomers exploring the realm of automation. We exchanged ideas, shared experiences, and discussed the latest trends shaping the industry.

Things look very promising for the automation and robotics community in this first industry event, and we look forward to witnessing where our shared passion for efficiency and innovation will take the industry next.

Keynote speech

On the second day of the expo, Dr. Nikos Kyriakoulis, Co-Founder and Managing Partner at CORE Group, delivered a captivating presentation on the main stage of the expo, addressing the key challenges facing the manufacturing sector in the era of Industry 4.0 and beyond. From the need for decarbonisation, to generating ESG-relevant business value, Dr. Nikos Kyriakoulis offered potential solutions to all high-stakes industry challenges, using the latest evolutions in AI and machine learning technology.

If you didn’t make it to the expo, or missed the presentation, a recording is now available on our YouTube channel. Simply follow the link below.

Stay in touch

We extend our gratitude to everyone who took the time to visit our booth and engage with our team. We look forward to continuing the journey of innovation and collaboration together.

See you all at the next event!

Transforming Greek manufacturing with COREbeat

CORE Group’s all-in-one predictive maintenance platform

is the go-to solution for EP.AL.ME., the leading Greek manufacturer.

Transforming Greek manufacturing with COREbeat

Author: Alexandros Patrikios

April 11th 2024

COREbeat, CORE Group’s signature product, is here to cover an inherent need of the manufacturing sector – the seamless operation of its production machines.

COREbeat is an all-in-one predictive maintenance solution, encompassing compact hardware, AI-infused software, and a web and mobile UI. COREbeat operates through collecting data using its built-in sensors in real-time, then employing machine learning algorithms to detect behavioural anomalies and and provide early notifications of upcoming failures.

The collaboration

Since last summer, COREbeat has been the driving force behind EP.AL.ME.’s predictive maintenance capabilities.

A subsidiary of MYTILINEOS, EP.AL.ME. is an Aluminium Recycling company that specializes in the processing and sorting of scrap metal and the production (smelting) of recycled Aluminium billets. Their collaboration with CORE Group started as part of the e-CODOMH cluster, whose mission is to upgrade entrepreneurship and create an added value in the Greek construction sector.

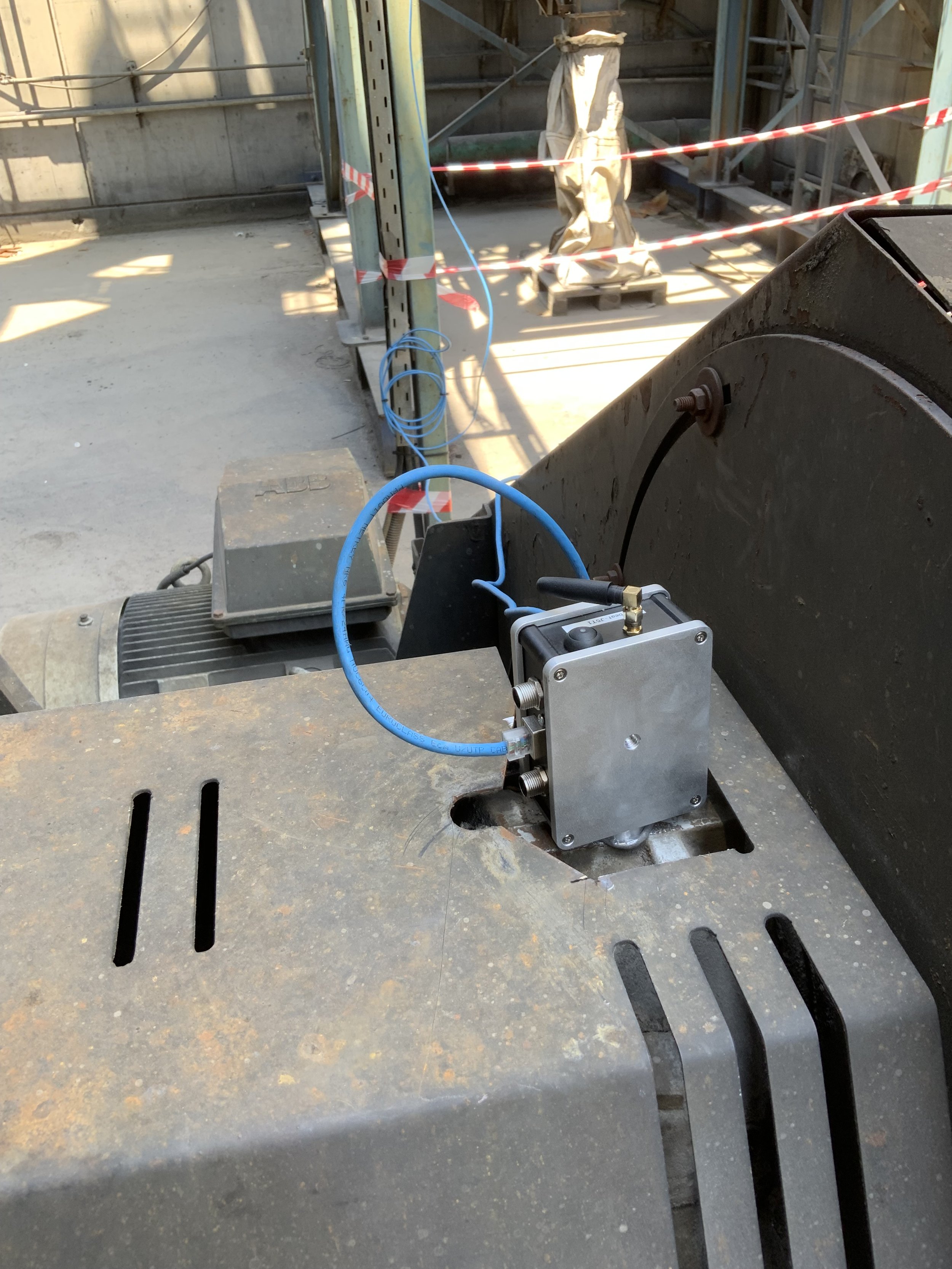

Installation

The initial installation of beatBox, COREbeat’s hardware component comprising IoT and Computing Edge devices, takes only 2 hours. Upon installation, employees can monitor the behaviour of their machine right away, through COREbeat’s intuitive User Interface. The predictive maintenance capabilities begin at 4 to 6 weeks, and that’s when COREbeat’s Deep Learning magic comes in at full force. After this initial training period, factory employees receive instant notifications through the app for any anomalies. This way, they know immediately whenever the operational health of a machine asset starts declining.

Below, we have some photos of the EP.AL.ME. installation by the COREbeat team.

How COREbeat helped EP.AL.ME.

EP.AL.ME. came to appreciate COREbeat’s predictive maintenance capabilities soon after installation. Maintenance employees at the facility were notified that one of the fans in the aluminum recycling facility was in critical condition, a few days after scheduled maintenance had already taken place. The factory staff, upon inspection, could not find the source of the malfunction, so they continued operating the fan normally.

In the COREbeat interface, the fan kept appearing to be in critical and worsening condition over the span of 2 weeks, which led the staff to pause its operation for an unscheduled maintenance check. During this check, they found an issue with the motor belt of the fan, which they would have missed without COREbeat. This saved the facility from unexpected downtime, delays in the factory’s production pipeline, and substantial losses due to production delays.

Find out more

COREbeat’s success relies on CORE Group’s long experience in the field of machine learning for manufacturing. With a long list of over 40 EU projects, CORE Group is turning into a household name in AI technologies and their industrial applications.

If you are interested in COREbeat’s predictive maintenance capabilities, you can reach out to our team and share more information on the needs of your manufacturing facility through info@core-beat.com.

The InComEss project wraps up

Authors: Clio Drimala, Dimitris Eleftheriou

19th March 2024

Having successfully completed 4 years of operations, the InComEss project officially wrapped up its activities last month, and held the project’s Final Review Meeting with the European Commission’s Project Officer on March 13, in Brussels, at the premises of SONACA.

With a core team of 18 partners from 10 countries, InComEss entered into force in March 2020. Now, after a four-year lifespan, the project has yielded remarkable results, including more than 17 open-access academic publications, and has driven outstanding research on the development of polymer-based smart materials with energy harvesting and storage capabilities in a cost-efficient manner for the widespread implementation of the Internet of Things (IoT).

CORE Group was involved in various tasks within the project framework to expand InComEss’s impact. In particular, we were responsible for devising and managing the consortium’s exploitation strategy, as well as leading the dissemination and communication strategy.

Project overview

Besides our involvement, overall achievements of the project include the development of:

Piezoelectric and thermoelectric energy harvesters with a proven ability to generate electricity through mechanical vibrations and temperature differences.

Monolithic printed supercapacitors that demonstrated their efficacy to store the harvested energy when integrated with a conditioner circuit and generators.

A power conditioning circuit that enhances energy transfer efficiency between generators and end-use electronics.

A miniaturized Fibre Optic Sensors (FOS) interrogator, with reduced power consumption, was showcased for its utility in energy harvesting.

Furthermore, Bluetooth Wireless MEMS and FOS communications were optimized and seamlessly integrated into an IoT platform, offering data monitoring capabilities. Among the research highlights being implemented within InComEss are also three impactful use-cases within the aeronautic, automotive, and smart buildings sectors.

Exploitation activities

The exploitation activities encompass an exhaustive market analysis targeting the consortium’s end users and other markets that could potential leverage the project’s innovations. The specific markets addressed were: 1) Smart Buildings, 2) Aeronautics, 3) Automotive, 4) Oil & Gas Pipelines, 5) Sports Environment, 6) Pacemakers, 7) Railway, and 8) GPS tracking devices. We identified market barriers that would slow down the adoption of the project’s technologies, which we categorized in regard to their nature (Sociopolitical, Economic, Environmental, Technological, Organisational). Based on the information provided, unique selling points of the results with commercial orientation were discerned.

Moreover, results were identified with a clear IPR protection path and exploitation route option. Partners decided whether they would use their results for further research or commercially. We developed business models for the more marketable results based on sustainability-oriented archetypes. The business model included the list of partners participating in the commercial exploitation and their associated activities and resources required to bring the system to the abovementioned market segments. Potential avenues such as ΣEureka and InnoEnergy were considered to reduce the initial investment costs and improve access to market.

The activities were manifested in the development of business plans for the Automotive and Aeronautics use cases. The analysis considered the potential benefits that the route-to-market partners would receive, namely Photonfirst and Smart Material and specifically the point where they would expect a return on their initial investment if they further progressed their results. Based on the activities and resources needed, an appropriate revenue model was in place to perform a financial analysis for both use cases. Moreover, we worked on a cost-benefit analysis for the end users to understand their benefit of acquiring the commercialized version of the InComEss system. Specifically, the aeronautics scenario included an installation in the wing slats, while the automotive scenario in the exhaust systems.

Dissemination and Communication Activities

When it comes to dissemination and communication (D&C), CORE devised and oversaw the dissemination and communication strategy, working hand-in-hand with the entire consortium to maximize the project's impact and resonance.

The InComEss team generated 17 open-access scientific articles, an important legacy of the project, and plans to publish 7 more in the upcoming months. Partners also participated in 32 events delivering 50 presentations and a lecture, presenting 5 posters and promoting InComEss through 2 exhibit booths and a stand in landmark industry-related events.

Beyond that, 2 workshops were organized namely, Mid-Term Workshop on InComEss EU Project and the InComEss Final Workshop. Video recordings from the workshops are available to watch here and on YouTube [Part 1], [Part 2]. 11 more short, engaging videos introducing the InComEss concept and recapping its research activities are also available on the project’s YouTube Channel.

The project’s website, designed and maintained by CORE, will continue as a central hub for useful information and resources. Visitors can learn more about important research activities performed and results through 11 press-releases, 10 newsletter issues, open-access scientific papers, public deliverables and training materials that can be found on the website.

The project has also shaped significant online communities, with more than 1000 followers on LinkedIn and 700 on X, another reflection of the overall effectiveness of the InComEss D&C strategy.

It has been a pleasure working with all our partners for the InComEss project.

Until the next one.

The MOSES project reaches a highly succesful conclusion

Authors: Pantelis Papachristou, Konstantinos Nikolopoulos

13th March 2024

After 3 and a half years, the MOSES project has reached its culmination, marked by a closing conference held online. The central goal of the project was to enhance the Short Sea Shipping (SSS) component of the European container supply chain by implementing the following three groundbreaking innovations:

The development of a hybrid electric feeder vessel, equipped with a robotic container-handling system, to increase the utilisation rate of small ports.

The establishment of a digital collaboration and matchmaking platform to match demand and supply of cargo volumes, utilising Machine Learning (ML) to maximise Short Sea Shipping traffic.

The introduction of an autonomous vessel maneuvering and docking scheme, based on the cooperation of a swarm of autonomous tugboats coupled with an automated docking system.

Our role in the project

As part of the project, CORE has been involved in the third innovation concept, pioneering the transition from traditional docking procedures to an autonomous swarm of tugboats. These advancements were facilitated by creating a sophisticated simulation environment and the application of ML techniques, which refined docking strategies. This digital twin technology, coupled with an AutoPilot control system, exemplifies a significant leap forward in maritime operations, reducing docking time and enhancing port service availability and environmental sustainability.

Machine learning approach

Initially, our team created a virtual environment to simulate the real-life components, such as the port, water mass, tugboats and containership. To ensure fidelity to actual conditions, the virtual environment integrated results from hydrodynamic simulations conducted by MOSES partners, analysing the navigation and evaluating the hydrodynamic parameters, such as the friction resistances for each ship object separately. Additionally, Finite Element Model simulations (FEM) were employed to assess the interactions between the tugboats and the containership, by evaluating force-reactions and stresses.

MOSES Unity test scene displayed during training of 3 push agents next to the “Advanced Ship Controller” and “Behaviour parameters” component.

The simulation environment served as a training environment for the developed swarm intelligence machine learning algorithm, allowing agents to learn from their experiences. Specifically, the agents (tugboats) were trained using deep reinforcement learning techniques, where the learning procedure is based on the interaction of the agents with the environment and the accumulation of feedback (rewards or penalties), while the agents collected observations through LiDAR and GPS sensors. The goal was to discover optimal strategies that maximise cumulative rewards over time. The developed digital twin was deployed at the edge, along with an AutoPilot system to control the steering and thrust of the tugboats based on the digital twin’s inference.

The digital twin was successfully demonstrated and validated in relevant environment (TRL6) at the Faaborg port in Denmark, employing a swarm of two tugboats pushing a bargue towards the dock. The accompanying video below illustrates the precision of the simulation outcomes (displayed on the left-hand side) compared with the actual real-world demonstration (on the right-hand side). This live demonstration underscored a remarkable achievement: more than a 25% reduction in manoeuvring and docking times, leading to a corresponding significant decrease in port emissions and a notable increase in the availability of port services.

Comparison of the simulation outcomoes (left-hand side) with the real demonstration in Faaborg port (right-hand side) considering the scenario where two tugboats push a bargue to the dock.

The commercilisation phase

To ensure successful commercialisation, CORE developed an Innovation Strategy, focusing on clear value propositions and competition mapping. Additionally, CORE developed a model for profit simulation, with a focus on the innovations introduced by the autonomous tugboat system, which is the only technology solution combining autonomous operation, sustainability and safety, with the highest TRL and exposed in real conditions.

Understanding our pilot

For more information on Pilot 1 of the MOSES Project, where our technical team was heavily involved, our consortium partners have created a comprehensive video explaining the AutoDock System and how it works. You can watch it below.

Over the past 42 months, we were very happy to work closely with our consortium partners to successfully deliver an autonomous vessel manoeuvring and docking system which has the potential to completely transform the Short Sea Shipping and container supply chain of the European Union.

We look forward to future, even more fruitful collaborations.

CORE Group contributes to new publication

Author: Dimitris Eleftheriou

6th March 2024

The latest open access book by Springer, titled “Artificial Intelligence in Manufacturing”, includes our work as part of the Teaming.AI consortium.

The Teaming.AI project

Teaming.AI is an Horizon 2020 project which aims to drive industry-wide change in smart manufacturing, through the introduction of higher customisation and personalisation of products and services in AI technologies. The main instrument is the development of an AI-driven Decision Support System, where decisions can be either taken by a human stakeholder or automatically by an AI service.

“Artificial Intelligence in Manufacturing”

The research findings of the project have led to a contribution in an academic book published recently by Springer, titled “Artificial Intelligence in Manufacturing”, edited by John Soldatos, which gathers findings across different EU research projects to provide comprehensive coverage of AI technologies and their various use cases in manufacturing, encompassing both Industry 4.0 and Industry 5.0 solutions.

This book, a part of the AI4MANUFACTURING cluster, features 27 chapters from the XMANAI, STAR, Teaming.AI, AI-PROFICIENT, Knowledge, MAS4AI, COALA, and KITT4SME EU projects. It presents a diverse range of innovative solutions for artificial intelligence (AI) in manufacturing. Our work for Teaming.AI is presented in Chapters 4, 5 and 23 of the book.

CORE Group’s contribution to the publication

CORE Group has contributed to Chapter 23, where we discuss insights and recommendations identified through the project, which can be used to design effective human-AI collaboration systems that enhance productivity, innovation, and social welfare.

Our main contribution lies in identifying existing issues when implementing human-AI collaboration systems in an industry setting. Through this demand-driven approach, our team was able to identify areas where further technological development was needed to ensure successful implementation of Industry 4.0 initiatives.

This process enabled the TEAMING.AI consortium to drive tech development with a market-first mindset. Our key findings show that end-users have a preference for easy-to-integrate, pilot-validated solutions with short-term value potential.

This publication is an important milestone for the project and the CORE Group team, which continues to produce cutting-edge research in the area of AI in manufacturing.

You can access the full book here. For more information on Teaming.AI, you can visit the dedicated project website, and follow us on LinkedIn and X.

CORE Group has moved to its new offices

Author: Alexandros Patrikios

December 11th 2023

This year, CORE Group has entered a new era, moving to our new offices in the south of Athens.

Since we moved this April, our working life has been transformed. Our new space is serving as an innovation hub, where we can collaborate, brainstorm and look at the problems we solve on the daily from different perspectives.

Designing the space

Last November, we started on a journey to reimagine our workspace. Our aim: to accommodate all 60 of our colleagues into a common space, and to make room for new talent as our team continues to grow.

Our new offices, covering a 1500 square meter area, were designed with meticulous care, to ensure that our space reflects our values and supports collaboration across our teams. Sprawling over three floors, our philosophy was to create a space that’s livable for our colleagues, not just filled with dedicated desks. Our ground floor offers just that; a central forum for our team, where we can meet, have impromptu one-to-ones, coffee breaks with colleagues, grab lunch, or simply just get to work in a more communal space.

Our working model

Our new space aligns with our hybrid working model, serving as a hub that brings us all together flexibly. The open space offers a dynamic approach, which encourages connectivity but also allows each of us to adapt our working space in a way that suits our individual preferences.

Our equipment

Besides creating a comfortable space for all our colleagues, we want to provide our team with the best possible tools to facilitate their day-to-day. We have invested in cutting-edge equipment, so our team can excel in their roles and perform their best every day.

A key highlight is the dedicated space we’ve created for our signature all-in-one predictive maintenance platform, COREbeat, and the rest of our state-of-the-art Industry 4.0 solutions. This space has been turned into a lab, where our team can focus its efforts on continuously improving our offering, where we have all the tools we need to test and validate our innovations.

A meeting space for all our collaborators

To facilitate our EU research activities, we wanted to make sure we can provide a space for all our partners across Europe. Highlighting our extroversion, we have created meeting spaces that can host large-scale meetings and industry-wide events.

Our ground floor was designed with just that in mind, to include a big meeting room and dining area. We have already hosted kick-off meetings, General Assemblies and Final Review meetings for some of our key projects and look forward to more events in the future.

Interested in checking out our space? We’ve curated a video of the construction process and the final look for our daily workspace just for you.

Check it out below.

CORE Group takes on 7 new EU research projects

Author: CORE Innovation Centre

20th November 2023

CORE Group and CORE Innovation Centre are continuing on our trailblazing EU research journey, participating in a total of 7 new Horizon Europe projects. Our new research projects, which focus on the digital and green transitions, will help us put our expertise to good use, always focusing on our four CORE missions; Digital Transformation, Digital Tools, Digital Twins and Green Industry.

The new projects bring our total to over 40 research projects, ongoing or completed, and increase our research budget to over 13 million €. We are very excited for our participation in all these new projects, a preview of which you can get below, and look forward to working with our partners to deliver impactful change through machine learning.

M4ESTRO

M4estro aims to revolutionise manufacturing with its trust-based Manufacturing as a Service (MaaS) platform, offering proactive resilience and disruption readiness. It aims to unite industrial stakeholders for secure service exchange and emphasize workforce development. The platform analyses internal and external factors, aiming for reduced process ramp-up times, enhanced efficiency, lower costs, and job creation, ultimately delivering a significant return on investment for the consortium. M4estro, beyond a research project, can serve as a transformative force for industry resilience and sustainability.

-

As part of the project, our team will create an optimisation engine to assess product entry into the value chain, providing ranked paths based on resiliency. The results are going to be displayed on an interactive web application, featuring frontend and backend connections, fetching industrial capacities, visualising optimal paths and calculating efficiency and resiliency scores. Under the M4estro framework, resilience strategies are going to be adjusted for each pilot, addressing multiple level manufacturing processes, value networks, human-centricity, and manufacturing assets by focusing on both the component-level development (vertical) and the process chain implementation (horizontal).

Our team will also drive dissemination and communication activities for the project, establish a strong visual identity, utilise diverse channels, and spearhead Intellectual Property Rights management, exploitation planning, and the development of sustainable business models for the M4estro solution.

METAWAVE

The Metawave consortium’s main goal is to implement advanced microwave-based heating systems in high-temperature heating processes in process industries, to enhance process efficiency, reduce energy consumption and lower greenhouse gas emissions. The project also focuses on integrating renewable energy sources through Virtual Power Plant configurations, accompanied by a smart Energy Management System (EMS), and fostering industrial symbiosis, ultimately achieving significant energy savings, emissions reduction, productivity increase, and economic growth for multiple stakeholders.

-

Our research team will lead the development of a smart EMS tailored for industrial microwave furnaces, forecasting the power demand and effectively managing the energy sources and storage components. Furthermore, we aim to utilise data-driven techniques, employing Machine Learning and Artificial Intelligence models, to support the development of a Digital Twin for modelling and optimizing the heating process. The findings of the EMS and the Digital Twin will feed a Decision Support System, accompanied by a friendly User Interface, so users can monitor and control of the heating process.

Additionally, we will define the necessary principles and provide support in the selection of scalable architectures, targeting to make the process industries metaverse-ready. Finally, our team will take charge of the exploitation and innovation management of the project, aiming to develop an exploitation roadmap to launch the Metawave technologies to the market.

CARDIMED

Cardimed is a ground-breaking project which aims to unite efforts for Climate Resilience in the Mediterranean region. As part of Cardimed, a digital framework that will be developed to harmonise Nature Based Solutions (NBS) data by engaging communities through smart tools and a multi-stakeholder strategy. Adopting holistic modelling tools for the Water-Energy-Food-Ecosystems (WEFE) Nexus approach, the consortium will aim to address socio-ecological challenges across 9 demo sites, using 47 distinct NBS for a total 83 interventions across sites. Participating regions and communities will establish the Cardimed Resilience Alliance, which will function as a vehicle for the expanding network, via upscaling existing sites and adding new ones. The project expects to have 28 regions and 70 communities by 2030, creating 8000 NBS sector jobs, leveraging 450 million € in climate investments. With 5 defined replicable use cases and the aim to identify 10 more through the project, Cardimed will lead in building a resilient, sustainable future by transforming aspirations into impactful realities.

Follow CARDIMED on LinkedIn and X (Twitter) to stay in touch with project updates.

-

CORE will contribute on the refinement activities of user requirements and will develop a cloud-based orchestration middleware for efficient data handling across diverse sources, ensuring security and scalability. We will also focus our efforts on industrial symbiosis through smart water management in the HALCOR demo site, developing designs for NBS and auxiliary solutions such as Digital Twins. Our innovation team will also contribute to the overall exploitation and wider outreach of the project’s outcomes.

SM4RTENANCE

The Sm4rtenance project is a transformative endeavour focused on improving the manufacturing industry through data-driven predictive maintenance and dynamic asset management services. It encompasses various tasks, from harmonising embryonic data spaces to developing innovative service models such as Manufacturing Asset as a Service (MAaaS). Focusing on technical building blocks, data quality standards, digital twin technologies, and AI model development, the projects aims to revolutionise the way the manufacturing sector works. In addition, the project addresses regulatory compliance and GDPR and promotes a collaborative, cross-sector approach.

You can find out more about the project on its dedicated website, or through following our consortium on LinkedIn and X (Twitter).

-

Our team will orchestrate and execute a comprehensive commercial exploitation strategy for the consortium, involving the monitoring and planning of commercial viability through market studies and concrete partner plans, integrating the Sm4rtenance solution into various product lines, technology enhancement, academic research, and knowledge transfer within research centers. We will also be involved in collaborative net-zero operation services for asset energy efficiency & low carbon dioxide footprint, with a focus on innovative data spaces.

TERRAVISION

Terravision aims to revolutionise the critical raw materials value chain with its integrated Earth Observation (EO) Mining Services Platform. Supported by four innovation pillars, the Terravision platform will leverage data from the Copernicus satellite, ground radar, drone, and in-situ sensing for comprehensive monitoring. Our consortium will introduce a novel framework for processing multisensory EO data, creating an open and standardised raw material spectral library. The EO services will cater to the mining industry's critical needs, including mapping of materials, mineral exploration, extraction rates, and hazard mapping for proactive risk management. A Green & Resilience Accountability component will be developed, to ensure sustainability by quantifying environmental and socio-economic impacts throughout mining phases. Demonstrated in the EU and beyond, and validated at 6 mining sites, Terravision can pave the way for impactful systemic innovations with EU-wide significance.

-

Our team will lead the UX design and user feedback phase, employing a co-creation approach to craft a user-friendly web development tool. This component will focus on delivering a modern web tool for monitoring and analysing data, incorporating advanced technologies and visualisation techniques.

We will also take on exploitation and innovation management activities of the project, analysing Key Exploitable Results (KERs), exploring exploitation routes, and assessing innovation potential. Intellectual Property Rights (IPRs) considerations, value proposition design, and sustainable business models for market-oriented KERs will be key activities driving our team forward. We will aim to address market uptake challenges for by analysing internal and external market barriers, developing roadmaps for commercializing KERs, and conducting competition and SWOT (strengths, weaknesses, opportunities and threats) analysis, to understand market dynamics and the competitiveness of the Terravision solution.

ARGUS

The Argus project aims to address challenges in monitoring remote built heritage assets, with a focus on preventive preservation. It aims to create a novel Digital Twin model for heritage, which will assist in the development of advanced digitization strategies, portable measurement systems, and AI-driven threat identification, assisting informed decision-making for the preventative preservation of heritage assets across Europe.

-

Our role in the project is to develop the Argus Decision Support System (DSS), a key component of the project that provides real-time actionable insights on risk assessment and mitigation. The DSS will leverage data collected from various sources to monitor damage thresholds and offer rich visual analytics, infused with predictive capabilities. It will also integrate external information on standards, protocols, and mitigation plans to enhance decision-making and safety measures for existing heritage assets.

GLAS-A-FUELS

The GlaS-A-Fuels project will focus on producing advanced biofuels, such as butanol and hydrogen, from non-land and non-food bio-wastes, to address energy security and environmental concerns.

It will employ a holistic approach, combining recyclable catalysts and a unique photonic glass reactor powered by solar energy to maximize the effectiveness of photo-amplified single-atom catalysts. This innovative process aims to achieve high catalytic performance and challenging reaction intermediates. The project leverages expertise in materials science, catalysis, laser technologies, and process control to develop efficient and sustainable production methods for these advanced biofuels, contributing to the EU's climate-neutral goals by 2050.

-

CORE Innovation Centre will have a high level of participation in the project, putting our technical, exploitation, communication and dissemination skills to use. Our engineering team will develop an intelligent software control system to explore various control theories, employing actual and virtual sensors. CORE aims to engineer the lab-scale solar reactor, by integrating it with process monitoring sensors and the control system which is embedded in an IoT-based system, leveraging different wireless technologies for high-level control and real-time monitoring.

Our innovation team will play a key role in maximising the project's innovation potential by evaluating the potential for the development of widely marketable solutions, the readiness of the industry for innovation, and innovation management. This includes creating an innovation roadmap and a detailed exploitation plan, as well as establishing suitable Intellectual Property Rights (IPR) protection methods, based on the technologies developed by the consortium.

Our communication team will collaborate with partners to ensure the consortium successfully reaches out to all stakeholders with its solutions and research finding. We will be leading dissemination and communication efforts, creating a distinct visual identity for the project and transmitting information using all relevant communication channels (social media, industry press, brochures, posters, newsletters, etc.). Additionally, we will hold technology transfer seminars, to present project results and facilitate integration of the Glas-A-Fuels solutions into targeted value chains, focusing on industrial trade fairs and scientific conferences.

The CAPRI project reaches its conclusion

Authors: Konstantina Tsioli, Ioannis Maimaris, Ilia Kantartzi

7th November 2023

After four years, the CAPRI project has come to an end with its final results and an online closing conference. CAPRI’s main goal was to develop cognitive solutions to the Process Industry, in order to facilitate its Digital Transformation. CORE Innovation Centre has been involved in various tasks as part of the project, and we are excited to see project outcomes reach their maturity.

As part of the project, our team developed advanced deep learning models for anomaly detection and Remaining Useful Life estimation of critical components in the asphalt use case. We were also responsible for delivering some of the consortium’s exploitation activities, as well as fully managing all project-related communication tasks.

The goal of CAPRI was to develop, test, experiment and deliver an innovative Cognitive Automation Platform which incorporates cognitive technologies, such as artificial intelligence, machine learning, and advanced automation, to enhance the operations within the Process Industry. Critical outcomes include actions to enhance the flexibility of operations, making the processes more adaptive and responsive, as well as actions to improve operational performance by reducing costs, improving maintenance efficiency, optimising resource utilisation and more.

Deep learning models

The deep learning tools developed by our team have been applied to a use case for asphalt production (EIFFAGE), aiming to reduce maintenance and spare parts costs related to critical operations and to enhance the reliability and robustness of the maintenance system. More specifically:

Anomaly Detection: By leveraging deep learning techniques, this model excels at identifying potential malfunctions in the machinery of asphalt use case. It acts as an ever-watchful guardian, constantly monitoring the baghouse system to alert for anomalies before they become critical issues. This proactive approach allows maintenance to be optimised and to minimise unexpected disruptions.

Remaining Useful Life (RUL) Estimation: Extending the anomaly detection model, our team went one step further by estimating the remaining useful life of critical components. In the EIFFAGE use case, the critical sensor is located at the entrance of the baghouse. This component is essential for maintaining the efficiency and quality of the involved processes. As an outcome, through our RUL estimations, we can accurately predict the time until the next failure of this critical component, offering manufacturers with the foresight needed to plan maintenance activities effectively.

CORE Anomaly Detection model for critical component constant monitoring and for providing possible alerts prior malfunctions.

These solutions have implications for other industries and, once applied, can potentially increase cost efficiency in the steel, aluminum and copper, cement, pharmaceuticals and glass manufacturing industries. More information on the EIFFAGE use case can be found here.

The commercialisation phase

Our innovation team contributed to the exploitation of CAPRI project outcomes by analysing the financial sustainability of the applicable exploitable results, utilising our custom Profit Simulation Tool. This endeavor aimed to gain insights into the financial requirements and resources necessary to introduce the solutions to the market and identify feasible scenarios for the commercialization phase.

This involved estimating Revenues and Costs for a 5-year post-project horizon. The knowledge accumulated throughout the project, which involved the analysis of market conditions and customer segments, was further developed, projecting this analysis into the future for the market. Initially, the analysis focused on customer segments related to the project use case industries, with plans to later expand to include industries identified through the replication analysis. Various scenarios were examined, to pinpoint a pragmatic and viable strategy for partners to implement so they can successfully bring their solutions to market and deliver a sizeable impact for CAPRI on the EU process industry, while also developing their business.

Communication activities

On the communication side, our consortium participated in 32 events over the years, with a total of 13 publications and 16 articles published. The project performed exceptionally well on social media, garnering over 900 followers on X (formerly known as Twitter) and over 1300 on LinkedIn. Additionally, our team ran a YouTube account, which hosts 21 videos with over 2000 views in total. The project website, which was designed by CORE IC and officially launched in the early months of the project, has gained 8400 visits in the three-year run of the project, and it will continue to serve as a central hub for all project deliverables.

It's been a pleasure working with our consortium to deliver cognitive solutions to the European process industry. To stay in touch with the project and its partners, you can visit the dedicated website, or follow the CAPRI accounts on LinkedIn and X.

CORE Group explores the rich history of wine

Author: Mina Tsatsani

November 1st 2023

This week, our team went on a thrilling guided tour of the Oenotria Land Vineyard, organized by our friends over at The Wine Connoisseurs. Our team went on a trip of wine through the ages, got to learn more about how wine is made (and tastes), and got the chance to qualify our very own wine connoisseurs in the process!

CORE’s wine trail started from our offices in the south of Athens, where our team gathered before heading to Kapandriti, in the north of Attica, to visit the Costa Lazaridi Oenotria Land vinery and wine museum. On our way, our guide from the Wine Connoisseurs offered an introduction to the history of wine in Greece, the trail vine cultivation followed starting from Macedonia and Crete, and the way wine has been consumed in the country since ancient times.

At the wine museum

Once we reached Kapandriti, we embarked on a guided tour of the wine museum, which boasts an extensive collection of exhibits dating as far back as the 17th century AD. Our team discovered the history of vine cultivation in an interactive way and got a glimpse into the processes of wine distillation and balsamic vinegar production. Our guide explained the different cultivation and distillation techniques used for various types of wine, the influence of grape-growing latitude, the significance of the region, and the stringent standards that shape the flavor of the wine. We finished off our tour with the aging process of wine and balsamic vinegar.

Wine tasting

Following our tour, we jumped straight into the highlight of our visit; wine tasting, accompanied by charcuterie. Our team tried out a wide variety of Lazaridi wines, identifying the distinct aromas of each one – and munching on the snacks offered by the Lazaridi team.

The making of a sommelier

We closed the day off with a competition. Our people split in different teams depending on their designated CORE mission and the types of projects they're working on! We split into four teams, Digital Transformation, Digital Twins, Digital Tools, and Green Industry. Each team was given one of the wines we all tried out during the tasting, and we had to guess the aromas, which wine we were given and answer questions on the history of wine. The winning team, Digital Twins, was given bottles of wine and certificates, qualifying them as our CORE wine connoisseurs. If you ever need a sommelier, CORE now has you covered!

Till next time

We headed home with our bellies and hearts full, and big smiles on our faces – nothing to do with our day drinking. It was a lovely day of bonding for our growing CORE team. A big thank you to Domaine Costa Lazaridi and the tour organizers, The Wine Connoisseurs.

The Level-Up project has wrapped up with its Final Conference

Authors: Dimitris Eleftheriou, Ioannis Meintanis, Yianna Sigalou

17th October 2023

After four fruitful years, the Level-Up Project has wrapped up with its final deliverables and a Final Conference held in Brussels, Belgium. The project aimed to develop a platform that extends the useful life of major capital investments.

As part of the project, CORE Innovation Centre developed a range of models using ML-based algorithms across different use cases. Our team was also responsible for exploitation and communication activities for the Consortium.

The aim of Level-Up was to offer a scalable platform covering the overall life-cycle of critical role, big industrial machines or their components, starting from the initial digital twins setup to facilitate predictive maintenance, modernisation actions to diagnose and predict the operation of physical assets, even to the refurbishment and re-manufacturing activities towards the end of a machine’s life.

Different machine learning models

The machine learning (ML) based tools developed by our team have been applied to 4 different manufacturing lines (ESMA, LUCCHINI, TOSHULIN, and IPC) at the component, work-station & shopfloor level, with different technologies used depending on the specific needs, and available data for each pilot line.

For ESMA’s cold forming press, our team implemented AI based anomaly detection (AD) algorithms using state-of-the-art Deep Learning (DL) architectures, such as Auto-Encoders and proprietary unsupervised learning algorithms. By utilizing vibration signals and a variety of IoT sensors placed in the equipment, the models can look for patterns in data that indicate failure modes for specific components (e.g. bearings) and provide insights in real-time for the machine operator.

The TOSHULIN production line consists of a large industrial vertical lathe (SKIQ16-v2), with the workpiece clamped on a clamping plate which rotates when in operation. The end-user requirement was to focus on the lubrication system of the cutting tool, to detect anomalies and assess its operation capabilities. To achieve this, we developed a combination of tools, which utilizes a forecasting model to predict the future machine states and the behavior of the oil particles, together with a flexible monitoring mechanism which utilises dynamic thresholds to detect anomalies.

LUCHINI is a full production line for machining railway axles, and for Level-Up we developed an AD procedure using multi-sensorial vibration data. The goal was to facilitate predictive maintenance for the two most critical machines of the production line. The AD procedure is currently at the on-line/production stage, and we continue to monitor the performance and accuracy of the models used.

For IPC/CRF’s pultrusion pilot line, machine learning algorithms for AD and quality control have been developed and integrated with their upgraded monitoring dashboard to assist the operator in decision making and process monitoring procedures.

A go-to-market pathway for the consortium

Our team also led on exploitation activities for the project, to maximise the impact of its results. We developed a detailed exploitation plan for 26 of the project results, across 6 different sectors for our Consortium partners. For each use case, a detailed business plan was developed, which included:

Innovation Management Activities: We analysed the external ecosystem through which Level-Up can evolve, using different strategic tools, like SWOT and Porter’s Five Forces. We analysed the market for each sector, as well as potential market barriers that might slow the adoption of the technologies developed.

Business Models: For each use case, we developed a detailed business model using the Business Model Canva tool, identifying unique selling points, customer personas, costs, potential revenue streams, and key go-to-market activities.

Exploitation Roadmap: We developed detailed exploitation roadmaps and commercialization analyses for the project technologies, accompanied by a 5-year financial plan, which partners can use as a reference in their go-to-market journey.

Reaching out to the community

Finally, CORE Innovation Centre was responsible for handling the communication and dissemination activities of Level-Up.

The project excelled on social media, attracting 904 followers on Twitter and 981 on LinkedIn. During the project, we created 22 videos overall, which collectively received over 3,600 views.

With support from our partners at AIMEN and Innovalia, we carried a series of summer workshops to showcase the project's final results. We also co-organized the project's final conference in Brussels, with more than 70 people in attendance.

Through its four-year run, our Consortium submitted over 7 papers in open access journals, with 4 more pending approval for publication, and attended over 60 industry or scientific events.

Level-Up has been a major milestone for CORE Innovation Centre & CORE Group, setting us on a mission to transform the way digital technologies are implemented in manufacturing & beyond. It has been a pleasure collaborating with our partners across Europe.

CORE Group at the Thessaloniki International Fair

Author: Alexandros Patrikios

September 22nd 2023

CORE Group participated at the 87th Thessaloniki International Fair that took place in Helexpo last week. Our team joined the expo with a custom booth, presenting CORE Innovation Centre, our research and innovation powerhouse, and COREbeat, our all-in-one predictive maintenance platform.

For the first time in its history, CORE Group was there at the 87th Thessaloniki International Fair with its core products, to meet new partners and collaborators and introduce them to our unique company culture, focusing on our four missions; digital transformation, digital tools, digital twins, and the green industry. The spotlight was on CORE Innovation Centre, our non-profit research organisation, and our signature predictive maintenance product, COREbeat. Nikos Kyriakoulis and Stefanos Kokkorikos, co-founders and managing partners of CORE Group, were there to greet attendees over the first weekend.

Our research powerhouse

CORE Innovation Center is your one-stop shop for Industry 4.0 and Energy & Resource Efficiency R&D. With an ever-growing network of strategic partners across the EU, Core IC is a leader in funding activities and technology development. Amongst the 40+ research projects CORE IC has been involved in across many sectors, we chose to spend some time on one of our key projects, Twin4Twin. Twin4Twin is an EU Horizon Widening project which aims to build an industrial ecosystem around the core principles of Industry 4.0, while elevating the research profile of CORE IC and its staff.

You can find out more about the project here.

Our signature product

While there, we also presented COREbeat, our all-in-one AI-infused Predictive Maintenance platform. COREbeat is the only predictive maintenance solution to provide with sensors and computation on the edge of your machine, with a box the size of a credit card. The product comes with backend and cloud computing capabilities, machine and deep learning, and an intuitive user interface to visualize sensor data with AI results. The product has already been validated in more than 18 use cases in different industries, and it only takes two hours to set up.

You can find out more about the product here and request a demo directly.

Lovely faces

It was a pleasure to spend the full week at HELEXPO, greet old partners and discuss on potential new collaborations with our expanding network. We got to share our CORE vision with over 300 attendees who stopped by our booth for some chitchat. We look forward to next year’s fair, with even more to share with all of you!

CORE wins in EYDAP competition | Predictive maintenance against water waste

CORE wins in EYDAP competition

Predictive maintenance against water waste

Author: Eleni Natsi

January 18th 2023

At CORE, we pride ourselves on adopting a different mindset with innovation ingrained deep in our DNA. Therefore, we are more than excited that we were selected among 150 ideas from Greece and won the second prize in the EYDAP InnoChallenge competition for our predictive maintenance solution that detects and ranks defective utility water meters.

The InnoChallenge competition was organized by EYDAP, the largest water supply and sewerage company in Greece in collaboration with MIT Enterprise Forum Greece and with the support of the Hellenic Corporation of Assets and Participations S.A. (HCAP).

The competition, which attracted great interest from private sector companies, startups and groups of researchers and scientists, is part of the HCAP Innovation Challenge series. The HCAP Innovation Challenge series was designed by the members of the HCAP Innovation Network (public corporations operating in critical sectors of the Greek economy) in collaboration with MITEF Greece to facilitate HCAP portfolio companies to develop, post and run their competitions with incentive prizes for challenges they find worth addressing.

The challenges published on the HCAP Innovation Challenge platform are primarily data-driven and require a combination of skills, knowledge and hard teamwork to solve. Through them, portfolio companies are looking for innovative solutions that are difficult to specify and therefore difficult to price but can bring great value and efficiency to their operations. In addition, the HCAP Innovation Challenge can serve as a national testing ground for the development of innovative, data-driven applications developed by local and international teams using technologies ranging from Big Data and machine learning to IoT and 5G networks.

Teamwork makes the dream work

Having a solid background in predictive maintenance, acquired after years of involvement in relevant EU-funded projects and with the development of COREbeat, our predictive maintenance platform, the challenge we undertook was to detect the possible faulty utility consumption hydrometers that currently exist in the water supply system of EYDAP, by using raw data from the field.

Our great team of engineers, Apostolos Chondronasios, Ioannis Meintanis, Ioannis Livieris, Manthos Kampourakis and Spyridon Fourakis rolled up their sleeves and developed a predictive AI algorithm that detects and ranks defective utility water meters.

Our prediction algorithm had the second-best performance in the competition category “Algorithm for predicting faulty utility consumption hydrometers in the water supply system of EYDAP” and our team received the prize in an awards ceremony held on the 24th of March in Athens.

We are honoured to have participated in this incentive prize competition with our innovative solution that can contribute substantially to the timely and efficient detection of faults and, consequently, to the reduction of water waste.

The EYDAP Innovation Challenge was an excellent opportunity for us to put our knowledge and experience to good use and to challenge ourselves with a significant real-life problem.

The prize we took is a strong incentive to continue the hard work, towards the delivery of sustainable solutions for the digital transformation of various industries, with the common good in mind.

The new era of autonomous tugboats and intelligent docking for large ports | MOSES project

MOSES project

The new era of autonomous tugboats and intelligent docking for large ports

Author: Manthos Kampourakis

January 11th 2023

Nowadays, hub port operations are becoming less efficient due to congested waterways, manoeuvring and berthing processes that are error-prone, time-consuming, costly, vulnerable to disruptions (e.g., strikes), and accidents with significant environmental impact. The MOSES project tries to tackle all these challenges by adopting an autonomous vessel manoeuvring and docking scheme that provides operational independency from the availability of port services. This innovative scheme is based on the cooperation of a coordinated swarm of autonomous tugboats that automates manoeuvring and docking where CORE Innovation is in charge.

The first part for which CORE Innovation was responsible was the design and development of a swarm of intelligent virtual tugboat agents, capable of both performing accurate docking of a large containership and coordinating their actions. The goal of the swarm was to pull off simulations of two virtual scenarios which demonstrate the added swarm intelligence factor. For the first scenario, starting from an initial distance of about 80m from the dock, the push tugboat agent’s mission, was to assist on berthing while the large containership would apply corrective movements using its bow thruster. The pull tugboat agent aimed at maintaining the mother vessel’s yaw angle close to zero. For the second scenario, a swarm of four tugboat agents in total learnt to assist on the berthing operation (two push agents) while again maintaining the mother vessel’s yaw angle (two pull agents).

In this video, the sped-up demonstration of the first simulation scenario, the accurate docking of a large containership, is displayed. The upper right corner displays the distance between a marked position on the tip of the dock and a point at approximately the middle of the starboard of the vessel. The bow thruster applies corrective movements to the yaw angle using a custom script. The whole system covers about 70m until it reaches the dock at a predefined distance. At this point, the two tugboats decelerate and then an automated system can take over for docking.

To achieve this, the Unity3D simulation environment and the 3D models of all involved actors were used. Real-world performance was achieved by calibrating the environment physics and the development of custom Reinforcement Learning algorithms led to the successful swarm training. All relevant information needed to accomplish each agent’s task were given as inputs; the location, acceleration, and distance of virtual LiDAR sensors. Propulsion and steering control outputs enabled agents’ navigation. Learning was achieved by employing tailor-made reward signals that directed the learning process in their policies and at the same time penalized undesired tugboat actions e.g., collisions.

The second part for which CORE Innovation is responsible within MOSES project, will be completed in 2023. The goal is to repeat the above-described process in a virtual environment using pilot-specific components and train a swarm of agents in a real-life pilot demonstration.

From Condition Monitoring to AI-assisted Anomaly Detection: An Industry 4.0 Paradigm

From Condition Monitoring to

AI-assisted Anomaly Detection:

An Industry 4.0 Paradigm

Author: Ioannis Meintanis

12th December 2022

Nowadays, digitalization and automation based on the interconnection of heterogeneous systems have become an integral part of our daily lives.

Behind all these buzzwords the main goal is to use technology and data to increase productivity and efficiency.

Industry is keeping pace with the latest developments by integrating new technologies that can boost its productivity and flexibility exponentially. Manufacturers are adopting new technologies, including Internet of Things (IoT), cloud computing, data analytics and Artificial Intelligence (AI) throughout their production operations.

Condition Monitoring

Condition monitoring (CM) systems are an essential element of this transformation. Predictive maintenance is based on the condition monitoring of the assets to determine whether they will fail during some future period and on taking appropriate actions to prevent the consequences of such failure. Monitoring machines with live sensor data enable humans and intelligent systems to use vast amounts of available data to extract useful information from their production processes, making it possible to reduce costs, keep downtime to a minimum and respond early to possible malfunctions or safety risks.

This of course requires that machines are equipped with instrumentation sensors that collect data and distribute them either locally or via the cloud. Typical sensorial data include temperature, power, torque, pressure, acceleration/vibration signals and more.

This transition is not cost free, but rather require investments on multiple fonts: from provisioning infrastructure material (HW/SW) to training machine operators to perform investigative work based on the new information provided by the CM systems. However, the benefits from adopting condition monitoring systems are multiple:

Planning and implementing predictive maintenance schedules

Reducing maintenance costs through effective maintenance planning

Maximizing production output through outage prevention

Reducing downtime by prolonging equipment life

The traditional way condition monitoring is used, is to observe the monitoring signals and impose hard-coded alarm limits that trigger further maintenance actions. However, such procedure is effective only in simple tasks and requires expertise and good knowledge on the process itself. In complex processes when there are hundreds of sensor measurements, which is often the case in practical applications, it is impossible to assess the health of an asset just by analyzing each measurement on its own.

AI-assisted anomaly detection

This is where AI and deep learning techniques come into play. Unlike a human operator, AI algorithms have no problems analyzing historical datasets for hundreds of sensors over a period of several years. Recent advances in deep learning have shown great performance in modelling complex tasks in various domains.

The basic idea is to utilize an autoencoder network to compress the multidimensional sensor data to a lower dimension representation, which captures the rich interactions between the various signals. It has been observed that as the monitoring machine degrades, the interaction between these measurements is changing which also makes the autoencoder reconstruction error to increase. This can be used as an indicator of machine health which allows us to move from the simple identification of a malfunction to the proactive correction of the underlying problem.

Despite the active research in the field there are still some open challenges related to the low anomaly detection recall rate, the anomaly detection in high-dimensional and/or not-independent data, the noise-resilient anomaly detection and the explainability mechanisms for predictive maintenance (PdM).

A Day Spent Differently

30th November 2022

We at CORE Innovation have always put forth an effort to help people and organisations realise their full potential. This pursuit comes with the realization that for many individuals among us, this journey starts with a disadvantage, one that can be difficult to overcome. That’s why we recognise that advocating for the transformation of industries and organisations alone is not always enough, and in the spirit of offering, we decided to dedicate some of our time in the service of another cause, to help, to offer some comfort and relief.

On the 30th of November, we spent the day at the facilities of the social initiative ‘O Allos Anthropos’, a social kitchen active in Athens, Greece, that offers free food for those in need. We helped prepare and distribute food, as well as clean the kitchen for the next day’s work. The initiative, which has been widely awarded and recognised, was established in 2011 by Konstantinos Polychronopoulos. It has responded to some of the worst crises offering free food and has been steadily setting up a Day Centre in Keramikos district in Athens, offering a wide range of support services (from childcare support to hygiene facilities for the homeless) as an open space.

You can support the initiative by donating food, money, or volunteering work.

COREbeat front-end design and why we chose React

COREbeat front-end design

Why we chose React

Authors: Alexandros Rezkalla, Elias Mantouvalos

14th November 2022

The structure, design, behavior, and content of everything seen on browser are termed as front end. The languages used for front-end development are HTML, CSS and JavaScript. Another name for front end is “client side”. It includes everything that the users experience directly: text, colors, styles, images, graphs, tables, navigation menus etc.

Contrary to front end, users will never interact with the back end directly. The front end is what users see and interact with, while the back end is everything that happens in the background.

The foundations for front-end development are the HTML/ CSS programming languages that produce static pages. As the need for interactivity is more and more in demand, Javascript, a flexible programming language was created and then different libraries and frameworks were developed by the community. A coding library is a collection of standard functionalities – pieces of reusable code such as math functions or others, that are inserted into the code as supplementary functions, whereas frameworks are complete tools that expand the productivity of their base technology (CSS, HTML, JavaScript).

Nowadays, we have a few options when it comes to frameworks. The most used, supported and well documented are React, Angular and Vue. They all do the same thing but in a different manner and with a different syntax. Angular is a full-fledged and opinionated framework that provides all the functionalities out of the box, but with a steep learning curve and increased complexity. Vue is much more flexible and simpler, but it becomes cumbersome for big projects. React has hit a sweet spot among its competitors since it is as simple as it needs to be but with enough rules making it suitable for the development of large-scale projects.

After careful consideration, our framework of choice for COREbeat web application was React. This decision was based on some key advantages:

· Documentation

· Community support

· Third party tools

· Wide selections of libraries

React offers the freedom to developers to choose the tools they need without the extra bundle that Angular comes with. That results in a smaller application size and a better development experience overall. While Vue does something like this, the support for React is much better. Acknowledging the importance of documentation and support, the Facebook team behind React constantly listens to the open-source community to implement new features.

Concluding, our goal is to provide the best user experience possible, while using state of the art technologies. We are always moving forward, constantly looking for new tools to add to our arsenal. We remain agile and open to try and test new, exciting technologies.

COREbeat Technology Pillars, a short intro

A short intro of

COREbeat Technology Pillars

Authors: Georgios Fiotakis, Nikos Monios, Andreas I. Mantelos, Dr Apostolos Chondronasios

26th September 2022

The COREbeat platform brings together cutting-edge technologies to facilitate easy deployment, security, and unparalleled accuracy. But what are those technologies exactly?

Here, we take a closer look at the technologies involved and the outline of COREbeat’s architecture.

The beatBox, which lies at the ‘Edge’, makes up the physical entity of the COREbeat platform. Looking past the controversy about the definition of ‘Edge’ in the Industry 4.0 era, we position the ‘Edge’ at the location/point where data are generated. At this ‘Edge’, we place an efficient computing hardware device (beatBox) able to acquire, process, communicate and even infer predictions. This way, the beatBoxes acquire vibration and temperature signals at the asset level using our own sensing module in sync with our in-house deep learning algorithms. The signals are transformed, packed, and securely transmitted using message broker and data streaming technologies to CORE Innovation’s own cloud platform.

The main goal of COREbeat’s cloud platform is to receive, persist, analyze, and distribute vast amounts of high-volume heterogeneous data in real-time between physically different computation environments, tailored towards Industry 4.0. The COREbeat platform exists within a hybrid computation environment composed of public (AWS, Azure, GCP, etc.), private, and IoT clouds, leveraging different benefits such as scalability, robustness, security and real-time computation.

Following the latest technology trends on cloud computing and orchestration, we are leveraging Kubernetes to construct an environment that allows us to manage and deploy our applications and services seamlessly and securely. The nature of our services demands us to utilize the modern software architecture paradigms. The COREbeat platform is designed based on a microservices architecture (MSA), an event driven architecture (EDA), while data persistence is achieved by a scalable data warehouse solution that will keep your data safe and always available.

To secure a platform such as this, we have considered and deployed machine (M2M) and human-to-machine (H2M) interactions. The COREbeat platform employs certificates, generated and assigned to each device. It uses an asymmetric encryption mechanism to secure end-to-end communication channels, while on a higher level, exposure of our services is secured through reverse proxies. Users and organizations need to be certain that their data are securely stored and distributed across their applications. A key security feature is the authentication & authorization of a platform’s users, which we implemented based on the OAuth 2.0 protocol. Although, there are considerably more practices for security used in different layers and locations throughout our architecture, these will be further explored in a dedicated instalment of our blog soon. Stay tuned!

CORE's technical results in the iQonic project

iQonic project

CORE's technical results

Author: Spiros Fourakis

22nd September 2022

Figure 1: Original wafer image (left) and corresponding defect detection result from CORE defect detection model (right).

The iQonic project is entering its last few months and the project’s final webinar will take place in the morning of September 22nd. The project centers around a scalable zero-defect manufacturing platform covering the overall process chain of optoelectrical parts, facing the challenge of dealing with the evolution of the equipment, instrumentation and manufacturing processes they support. CORE’s efforts focused on deep learning algorithms to ensure strong prediction and detection skills and respective reactions to achieve zero defects.

More specifically, within the iQonic project, CORE has developed a new complete framework for defect detection and quality prediction of final assembled product in two demo cases AlPES and Prima. In particular, CORE’s contribution for Alpes Demo Case concerns the development of a machine learning-based defect detection solution which is focused on defect identification on the wafer parts (Figure 1).

Figure 2: Validation in early anomaly detection

Concerning the Prima Demo Case, a new and complete framework for prediction quality of a multi-laser emitter product, based on deep learning models was developed. The framework consisted of two stages: (1) early anomaly detection, focused on investigating the suitability of the final assembled product during early production stages, and (2) accurate prediction, which focused on estimating the quality index of the final product from its’ early production stage. Both models were successfully validated with real offline data from the production line. Especially, the anomaly detection model correctly predicted all the normal assemblies and nearly all defective assemblies, with only 3 false negatives (Figure 2).

Figure 3: Validation in accurate prediction of total power

Similarly, the quality prediction model demonstrated considerably low prediction errors and good generalisation performance (Figure 3).