EcoSync – CORE IC’s Advanced Conformance Checking Tool developed under the AUTO-TWIN project

Athanasia Sakavara | January 29th 2025

EcoSync – CORE IC’s Advanced Conformance Checking Tool developed under the AUTO-TWIN project

What EcoSync solves and how it alignes with CORE IC's mission

In complex industrial and operational environments, organisations rely on control policies to ensure compliance, efficiency, and strategic alignment. Yet in practice, everyday operations often drift from these predefined rules. This gap between policy and execution can lead to compliance risks, inefficiencies, and hidden operational costs that are difficult to detect with traditional audits.

EcoSync, an advanced conformance checking tool developed by CORE Innovation Centre within the AUTO-TWIN Horizon Europe project, addresses this challenge by transforming compliance into a continuous, data-driven process. The tool reflects CORE IC’s broader mission: bringing research results closer to real industrial application through practical, deployable Industry 4.0 solutions.

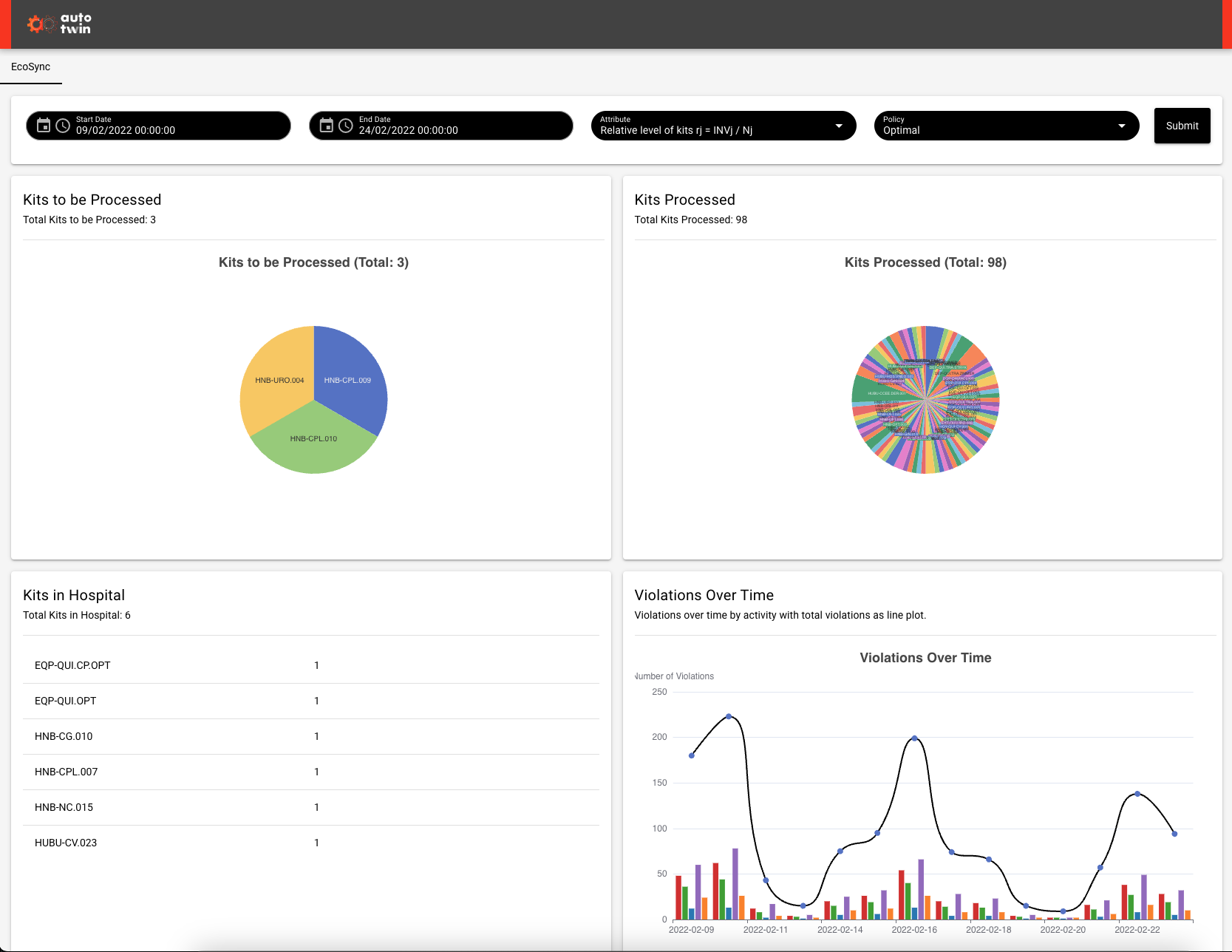

EcoSync's Dashboard

1. From Policy to Practice: What EcoSync Solves

EcoSync enables organisations to systematically compare real operational behaviour with predefined control policies. Rather than treating compliance as a retrospective exercise, the platform supports proactive monitoring and decision-making, helping teams identify deviations early and act with confidence.

By combining process mining techniques with policy-driven analysis, EcoSync aligns operational reality with organisational intent, supporting both regulatory adherence and performance optimisation.

2. How EcoSync Works

EcoSync follows a modular, data-driven workflow designed for clarity, transparency, and action:

User Input

Users define compliance parameters and evaluation rules through an intuitive interface.Data Retrieval

The platform connects to a System Knowledge Graph to access real-time process execution data.Conformance Checking

Actual workflows are compared against expected behaviour defined by control policies.Actionable Reporting

Results are presented through a clear dashboard, enabling both technical and non-technical teams to monitor compliance and track deviations in real time.

A key differentiator is EcoSync’s intelligent violation management. Detected deviations are automatically classified by severity, allowing teams to prioritise critical issues. For example, a high-severity alert is triggered when an object is misplaced beyond an acceptable threshold, signalling a major process disruption that requires immediate attention.

3. Flexible Policy Framework for Real-World Operations

To accommodate the complexity of industrial environments, EcoSync supports two complementary policy types:

Optimal Policies, derived from optimisation engines and representing the most efficient workflows based on data.

Custom Policies, defined by users to reflect specific regulatory, operational, or organisational requirements.